Success at LIGNA 2025: A New Era in Intelligent Scanning

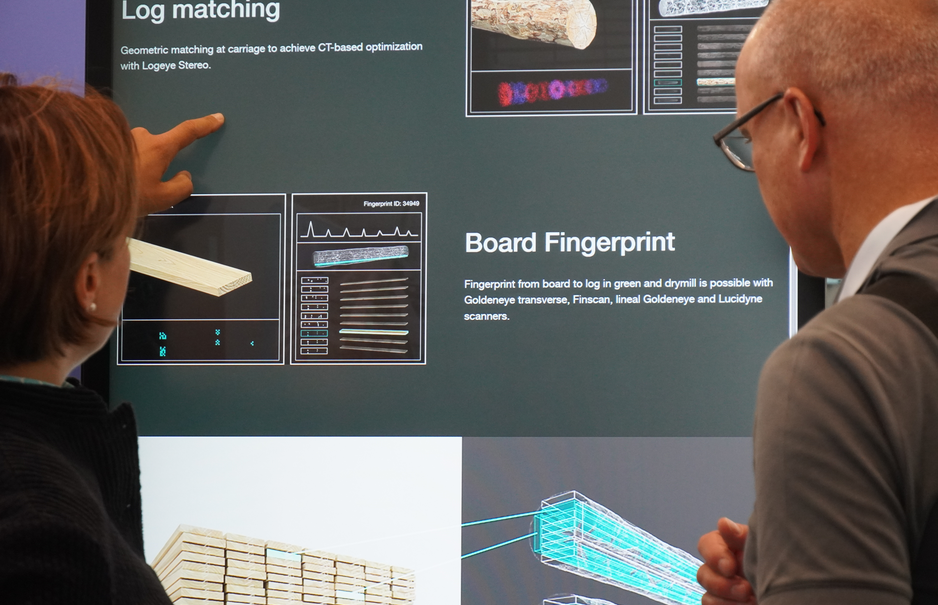

CT Cross-Training – When one scanner trains another

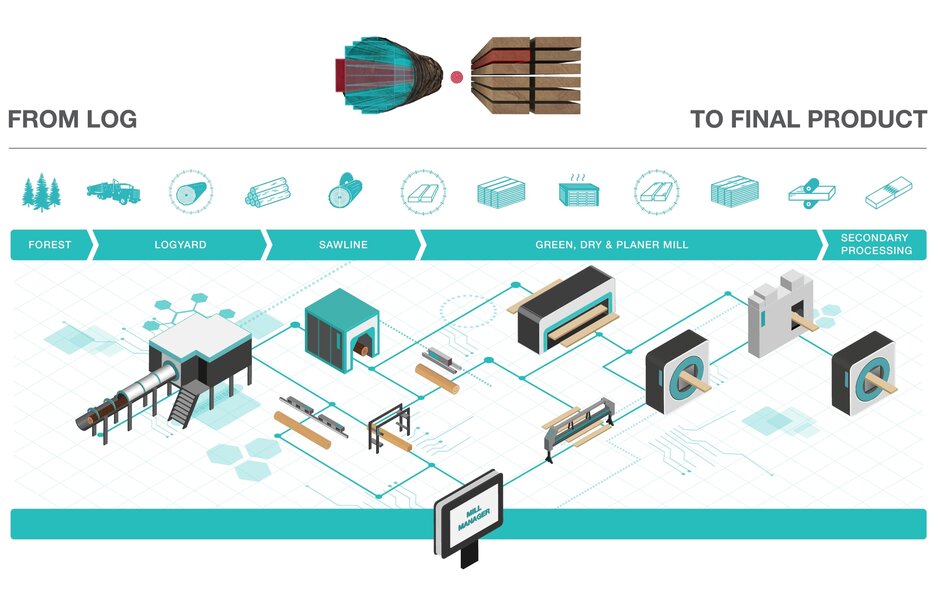

With CT Cross-Training, MiCROTEC is redefining scanner technology: For the first time, scanners can learn from each other and access insights based on computed tomography data. This significantly improves optimization and grading processes, thereby maximizing the yield from the valuable raw material, an aspect that is ultimately also reflected in operating results.

By connecting MiCROTEC CT technology with the company’s Ai platform, complete reconstructions of the internal characteristics of the logs and CT scan data can be transferred to other scanners within the network. Even scanners not designed to detect internal wood properties benefit from the scanner data.

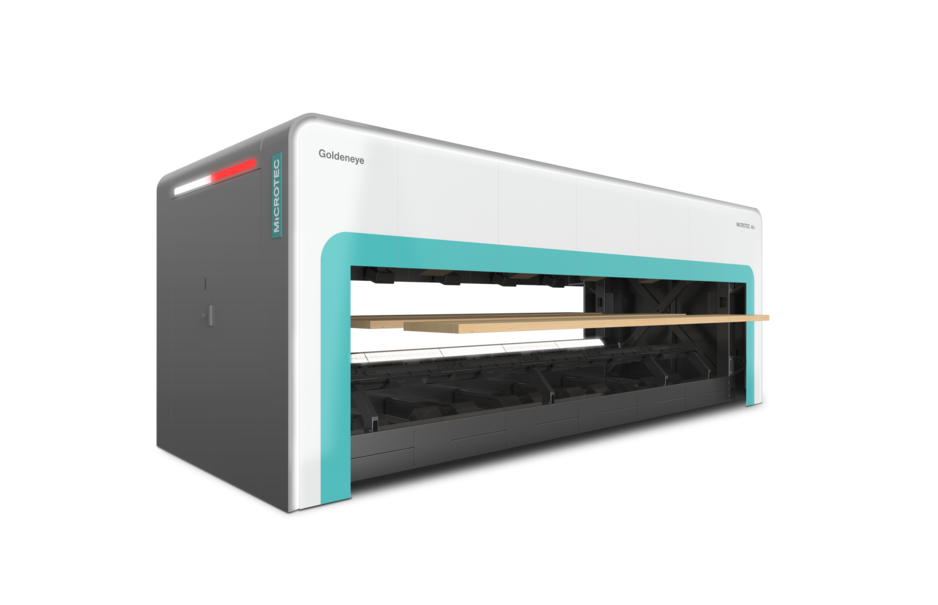

Next-Generation Logeye and Goldeneye 900

A standout highlight at the booth was the latest version of the Logeye multi-sensor scanner. With an optimized design to facilitate the retrofitting, new high-resolution color camera and the new motion compensation module. It delivers unparalleled precision in log data acquisition—from 3D measurement and color detection to X-ray technology.

The new Goldeneye 900 also impressed with a smart new design that combines top performance with improved serviceability. Thanks to generative neural networks fueled by CT Cross-Training, it now detects internal wood features such as the pith location—taking grading accuracy and operational efficiency to a whole new level.

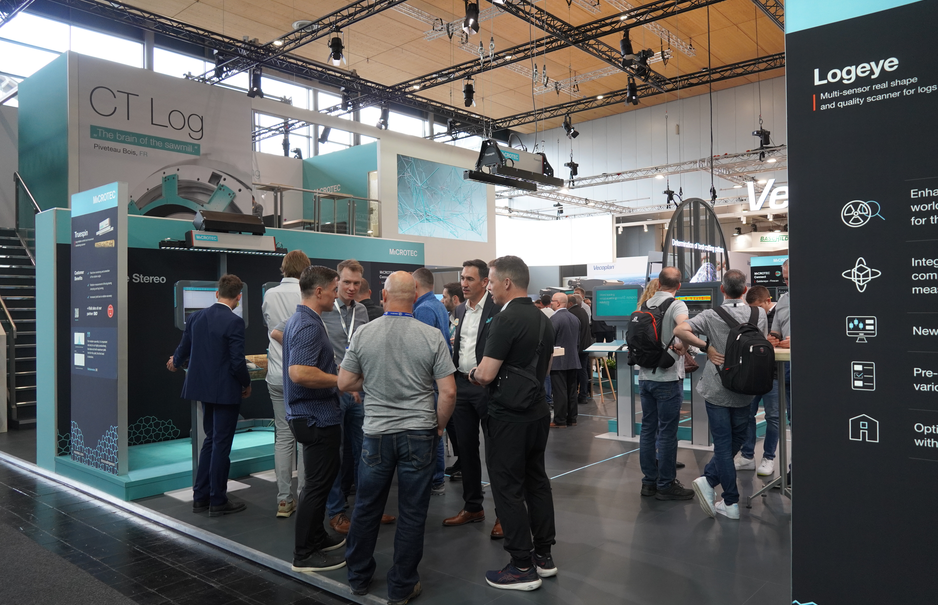

Conversations and insights

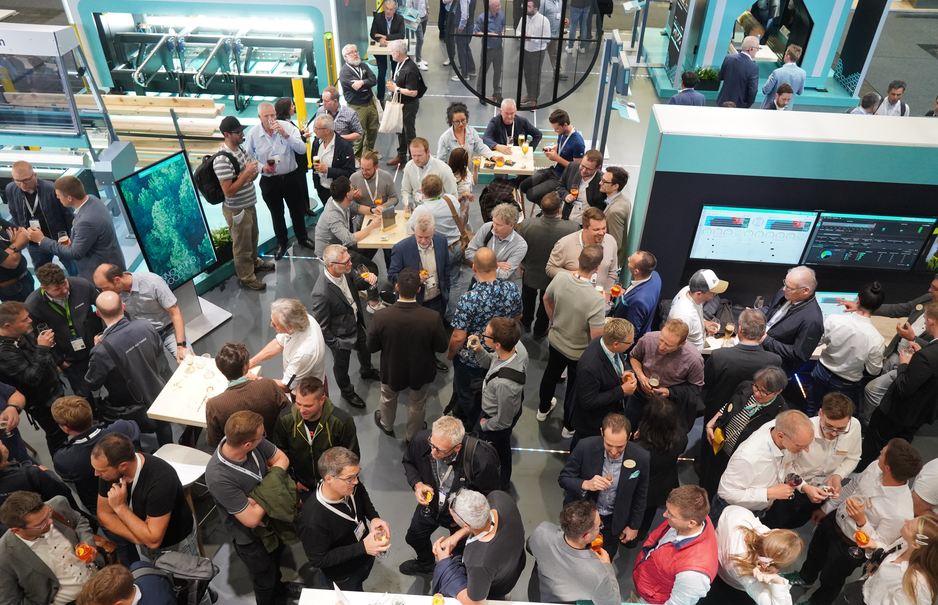

MiCROTEC’s Customer Care Bar provided a welcoming space for open dialogue and personal exchange. Our international team from sales, product management, and customer suport was excited about the great interest, the many exciting conversations and the specific project enquiries.

We would like to thank all the visitors who made our exhibition stands a lively place of innovation - and we look forward to working with our customers to make wood processing smarter, more efficient and more connected.