It's what's inside that counts

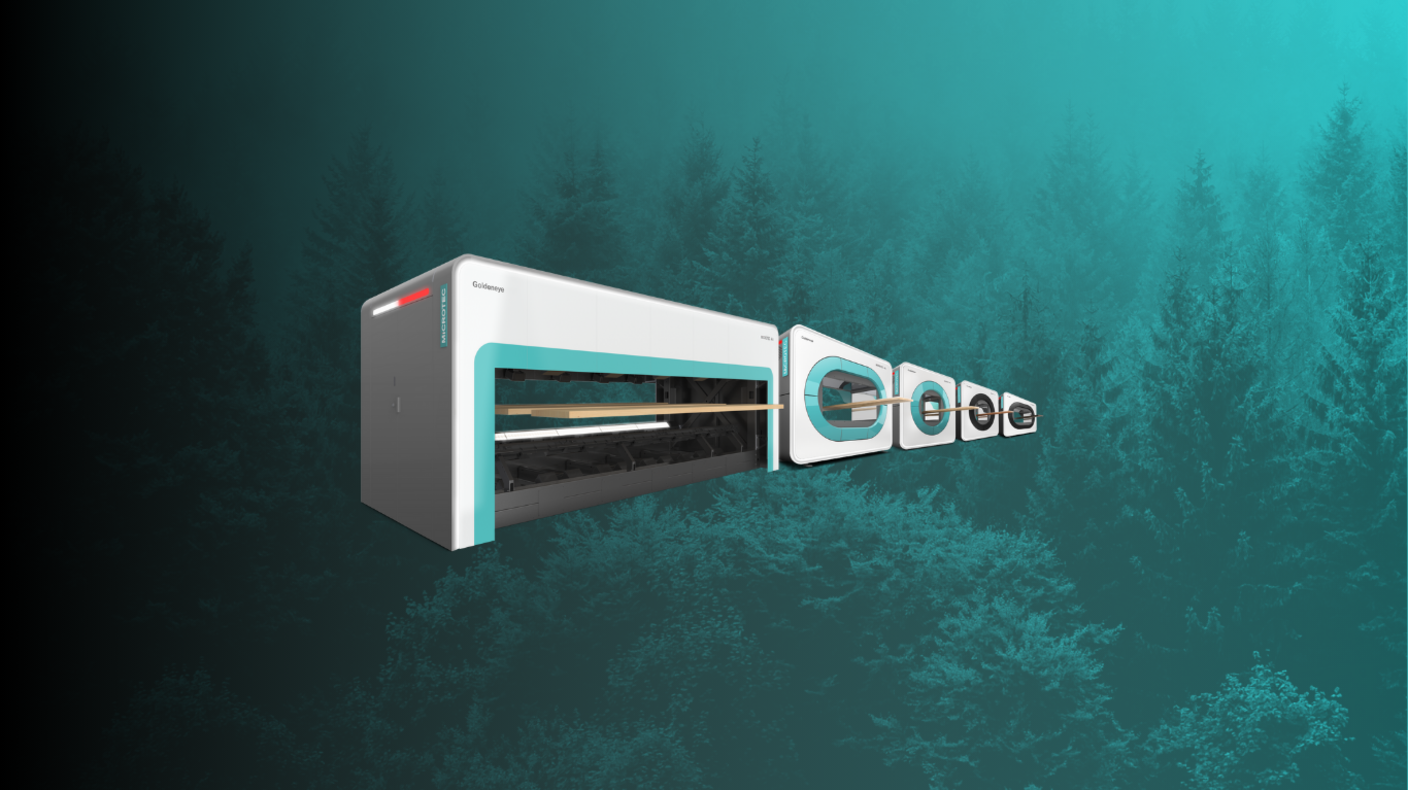

MiCROTEC offers a whole range of scanning solutions for all quality requirements of the timber industry. One example is the Goldeneye 900 transverse quality scanner, which was developed specifically for high throughput – for example, for large volumes of planed timber or standard timber construction products. The latest generation, which was presented at Ligna, is much more compact and features a side service door for streamlined cleaning and maintenance. According to the manufacturer, this feature also makes it easy to integrate the Goldeneye scanner into existing production lines.

For linear processes, such as in the production of CLT or solid structural timber, the Goldeneye longitudinal quality scanner for softwood, which has been established over several product generations, is the ideal solution. The lamellas are optimized in fractions of a second – at feed speeds of up to 1,200 m/min. The portfolio is complemented by the Goldeneye Wide, which can process boards with widths of up to 860 mm with the same high precision. MiCROTEC also offers solutions for the hardwood industry: In addition to the Woodeye scanner, the Woodeye Wide is available for the processing of particularly wide hardwood lumber. Thanks to MiCROTEC’s over 30 years of experience in this area, customers can rely on the highest detection accuracy and a significant increase in their respective in-house added value.

Multi-sensor technology meets AI

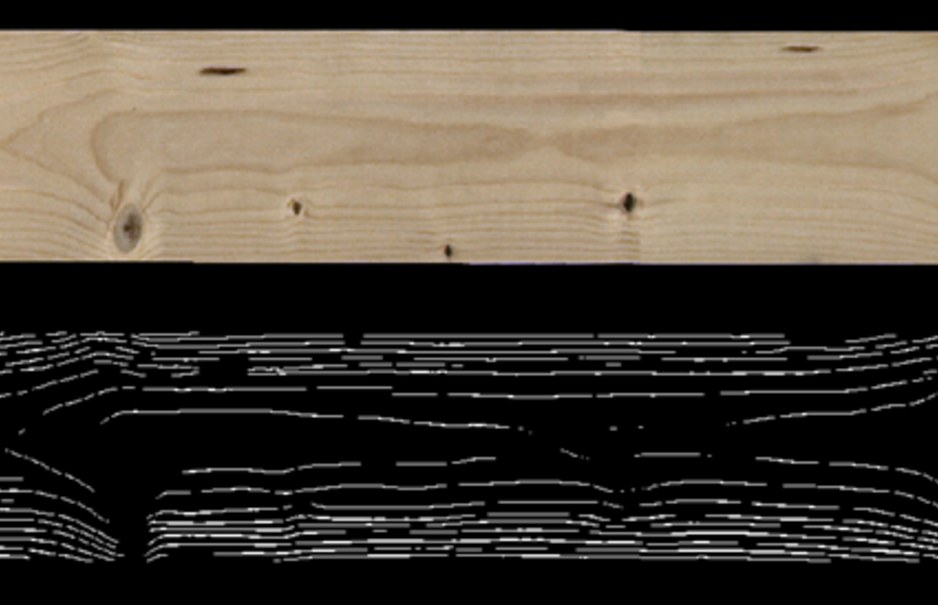

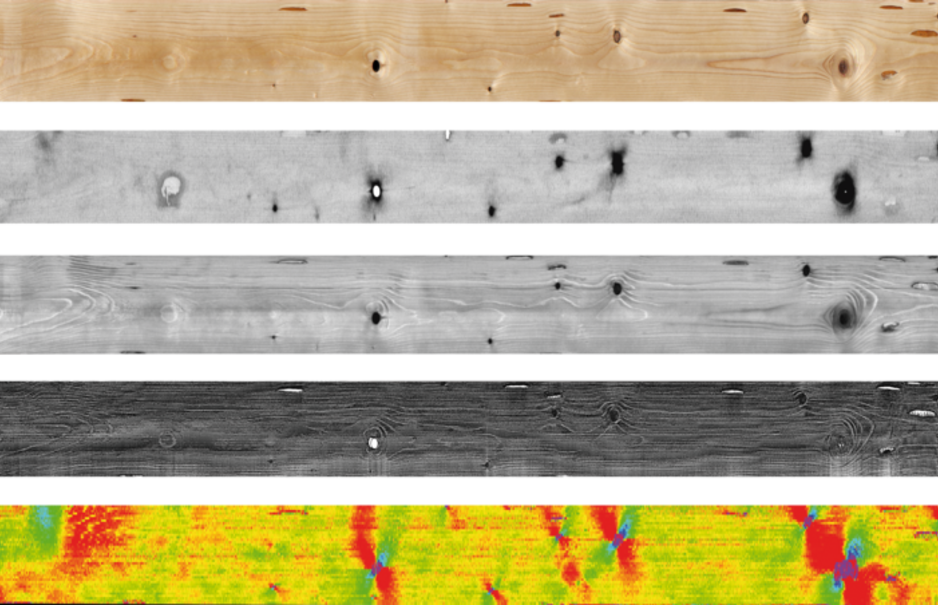

For the precise detection of wood defects, the state-of-the-art technology uses a combined multi-sensor system consisting of 3D laser, color imaging, scattering laser and, optionally, X-ray technology. This way, external and superficial defects as well as hidden defects inside the wood can be reliably detected and classified. The scanner can handle planed, rough-sawn, and even green lumber. According to the manufacturer, the scanner systems thus offer a unique, holistic package, as “different requirements and production phases can be flexibly addressed, and the wood can be classified in all process steps – all with just one scanner model”. The advanced integration of artificial intelligence further increases accuracy: CT scans from the log sector train neural networks, which in turn are used in lumber grading. This process – referred to as CT Cross Training at MiCROTEC – enables consistent quality assessment based on large, valid data sets.

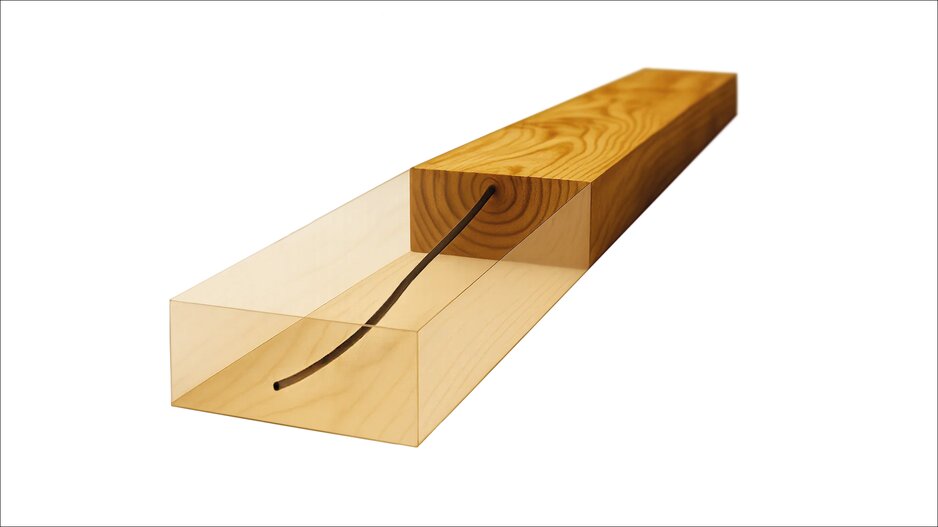

New features: Pith and annual ring location detection

With the new pith detection, MiCROTEC addresses a key quality criterion. Even if the pith is not visible, it can be precisely located thanks to the intelligent fusion of visual color image data and geometric 3D data sources. The underlying CT technology provides a highly accurate reference base – without the need to rip-cut the logs. Especially in strength grading according to US standards, the position of the pith plays a crucial role in correctly connecting the knots across the board’s cross-section. In further processing, however, the goal is to avoid having the pith in the final product.

The new AI-based “Growth Ring Map” also enables the targeted optimization of the annual ring pattern – a crucial factor in high-quality uses of wood, such as door, window, or furniture production.

Proven benefits for customers

To date, more than 1,000 linear scanners as well as 100 Goldeneye transverse quality scanners were installed worldwide, proving MiCROTEC’s global success. Users report significantly higher yields generated from the same volumes of raw material.

According to MiCROTEC, an investment in scanner technology pays for itself within a short period of time through increased value and quality output. At the same time, the number of staff required for quality assurance is noticeably reduced.

Interconnected systems as a strategic advantage

With their latest further developments, the South Tyrolean scanner experts are setting new standards once again. MiCROTEC Connect also ensures that new systems can be seamlessly integrated into existing production lines. Furthermore, all machines – from log scanners to final sorting – can be connected to form a fully adaptive overall system.

In conjunction with the centralized and intuitive Mill Manager, the complete software solution for analysis, monitoring, and planning – from log to final product – all relevant process data is made available for sorting optimization, machine control, and continuous efficiency improvements.

This way, MiCROTEC addresses key challenges facing the industry, such as rising energy and labor costs, as well as more demanding requirements regarding sustainability. These challenges and potentials are of great interest to all companies in the timber industry and need to be leveraged – together with MiCROTEC as a partner.

The full article from TIMBER-ONLINE can be found here.