Computed Tomography: Expert insights

We spoke with Enrico Ursella, Head of Advanced Research Management at MiCROTEC and one of the pioneers behind CT Log. Enrico has been closely involved in bringing CT technology from the laboratory to the sawmill floor, making it a powerful tool for the wood industry.

In today’s market, where raw material costs are high and efficiency is critical, CT has become more relevant than ever. The ability to look inside each log before sawing allows sawmills to maximize yield, make better decisions, and secure competitiveness in an environment where every percentage point of optimization matters.

In this interview, Enrico explains the fundamental differences between CT and conventional X-ray systems, the role of artificial intelligence, and why CT is becoming an essential element in fully optimized, AI-driven sawmill operations.

CT scanning is the most accurate method for log optimization. What makes the technology so fundamentally different from traditional X-ray systems?

While both use X-rays, they are fundamentally different in how they acquire and process information.

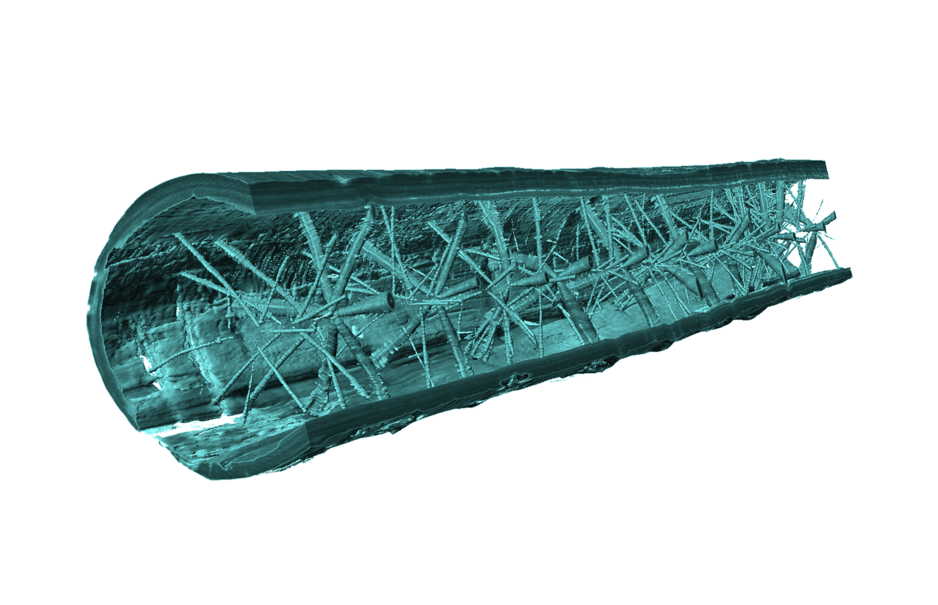

Think of a traditional X-ray system like a single photo. It captures a two-dimensional image of the log, essentially a shadow. Instead of a single photo, a CT scanner takes hundreds of X-ray images from a full 360-degree rotation around the log and creates a complete 3D model with all the details hidden inside.

This is why this technology is so revolutionary. For example, in medicine, we've moved from simple X-rays to CT scans and MRIs because a 2D shadow most of the time isn't enough to make a precise diagnosis. A CT scan gives doctors the detailed internal map they need to plan a surgery correctly, avoiding costly and dangerous mistakes. The same principle applies to airport security and other high-stakes applications.

In the wood industry, this level of detail allows for far more precision. As an example, we can accurately identify and classify not just the “knottiness” of a log, but also the length, diameter, and position of each knot, including where it changes from sound to dead. This amount of information enables better grading, optimization, traceability, and improvements at every step of production. While other X-ray scanners with one or two projections exist for sawmills, only MiCROTEC's CT Log is a true computed tomography scanner.

Why did you start to develop a CT scanner for logs?

Initially, the idea was just to create a laboratory system for training our own systems; twenty years ago, it was already clear to us that having reliable data for training was crucial. That scanner is still in operation at FVA in Freiburg. Once the first CT Log was completed, we realized it wasn't that complicated to make it directly usable in a sawmill. By then, not only did nearly every hospital have one, but so did an increasing number of airports and industries—a trend that has been accelerating rapidly in recent years. More and more applications see tomography as an investment with a quick return because it provides precise, reliable, and very detailed data.

Today, many sawmills optimize their processes around the information gathered by CT Log from each log. This has allowed them to significantly improve efficiency, production planning, the optimization of new product choices, and much more. The level of detail collected allows CT Log scans to be used also as a tool for scientific analysis on huge volumes of data. In fact, we recently published an analysis on wood quality, together with INRAE and Siat, based on scans of almost a million logs.

This enormous database is also useful for us to improve all our other scanners. Thanks to new artificial intelligence techniques, it's possible to drastically improve the performance of any system, provided you have a large dataset to train it with. CT Log provides us with a large quantity of high-quality data.

How has artificial intelligence changed the use of industrial tomography?

Artificial intelligence has tremendously improved the use of available data. For a decade, we have been using AI both to analyse the images produced by CT Log and to use these images to improve our other measurement systems. In artificial intelligence, the two most important things are having a large amount of data and a correct ground truth. You can't teach a child something by constantly confusing them with contradictory information. They risk learning muddled concepts and end up mimicking incoherent behaviours. We all know by now that AIs sometimes "hallucinate," meaning they invent things that are plausible but not correct. For this reason, CT Log images are fundamental for us. They provide us with real, precise data for the proper training of neural networks and all our systems.

Sometimes you hear that all you need is a million images to train an AI model. This is partially true for AI models that deal with language, like ChatGPT; in that case, they learn a bit like a person who goes to a foreign country without knowing the language and learns it by being with the locals. However, if we take a new operator and bring him to a sawmill without anyone to explain how the different qualities of wood are defined, can we expect him to learn to understand the regulations and selection rules on his own?

Having data on millions of logs without real and reliable data on their actual quality means risking the creation of millions of unreliable data points. Generative AI can have many creative applications, but it also carries the risk of incorrect decisions. Only a knowledge of reality enables reality-based training.

Many still see CT as complex or overengineered. What would you say to those who think it's too advanced or difficult to implement in a sawmill?

It’s true that the underlying technology is complex, but its real value is in how it simplifies and improves our work. A smartphone contains an amount of technology that would have seemed impossible only a few decades ago, yet now we all have one in our pockets.

Think about airports. For years, security used traditional 2D X-ray scanners for carry-on bags. They were simple, but inefficient. Now, airports are rapidly moving to CT scanners for baggage. The technology behind it is incredibly complex, but the result is a simpler, more accurate process with advantages for everyone.

Looking ahead, what role do you see CT playing in the evolution of fully optimized, AI-driven sawmill operations?

CT Log is the central nervous system for the fully optimized, AI-driven sawmill. A sawmill's success relies on a mix of products, customers, and pricing, all managed by expensive human experience. Profit margins are often slim, and a single wrong decision—from cutting a log incorrectly to choosing the wrong production mix—can be costly.

This is where AI changes everything. We are moving toward a future where a skilled AI assistant helps with every decision. This AI will guide immediate choices, like how to cut a log for maximum value. It will assist with day-to-day operations, suggesting which log piles to use for today's production. And it will even help with long-term strategy, identifying new, profitable products based on the raw material you have.

For this to work, AI needs precise information. That’s why our CT Log is so fundamental. It provides the detailed quality data for every potential board. This is combined with our MiCROTEC Connect fingerprint, which tracks each piece throughout the production line, and our Mill Manager database, which holds and analyzes the entire history of every piece. Together, these tools provide the comprehensive, real-time data an AI needs to turn a complex operation into a lean, profitable system.