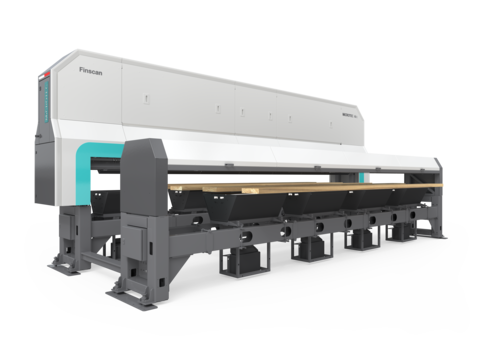

Smart Design for easy maintenance

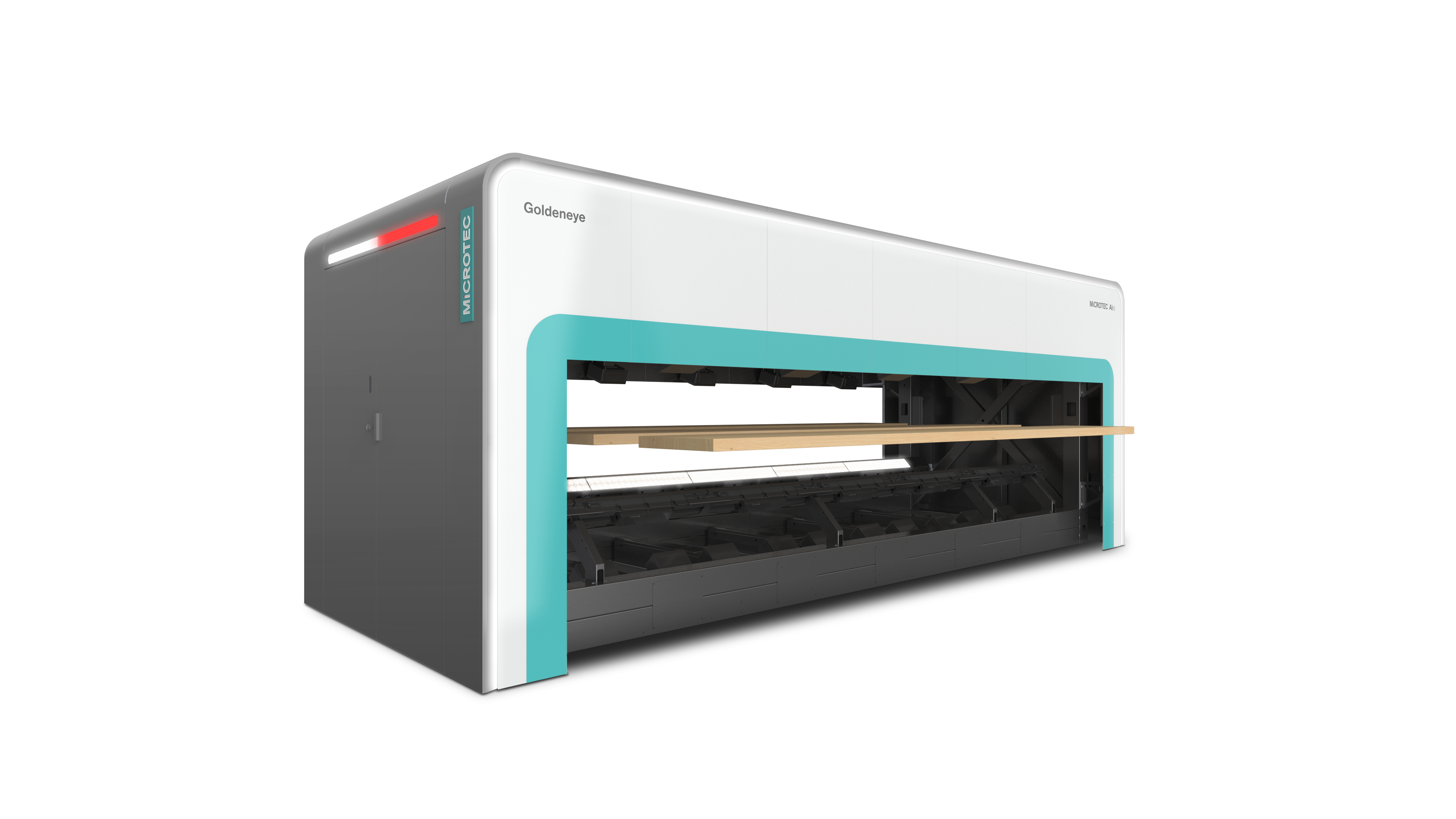

The Goldeneye 900 features an optimized mechanical design that streamlines maintenance by incorporating a side service door and providing easier access from both the infeed and outfeed areas. These enhancements facilitate cleaning, calibration, and servicing, significantly improving accessibility to the scanning area.

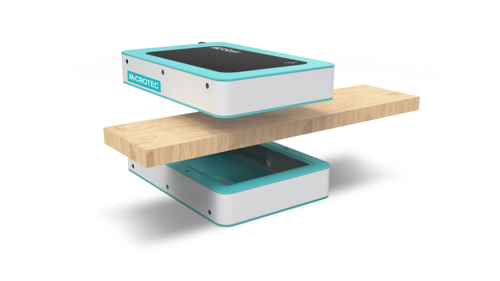

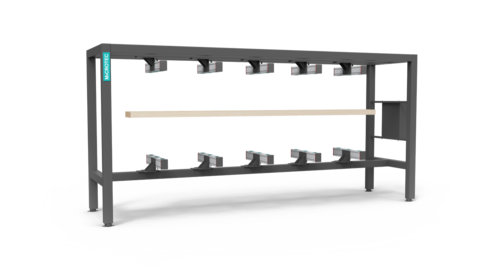

Seamless integration

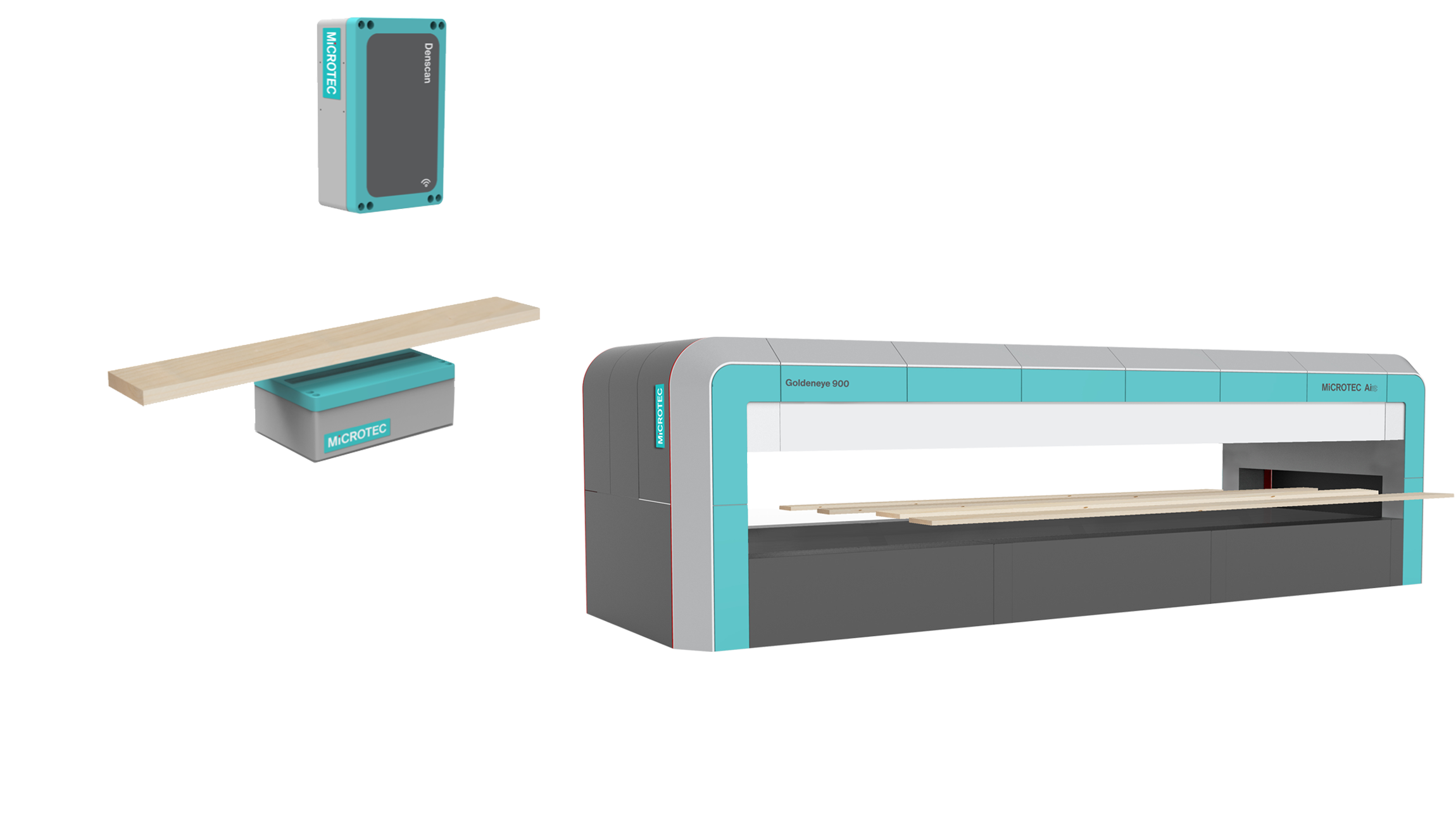

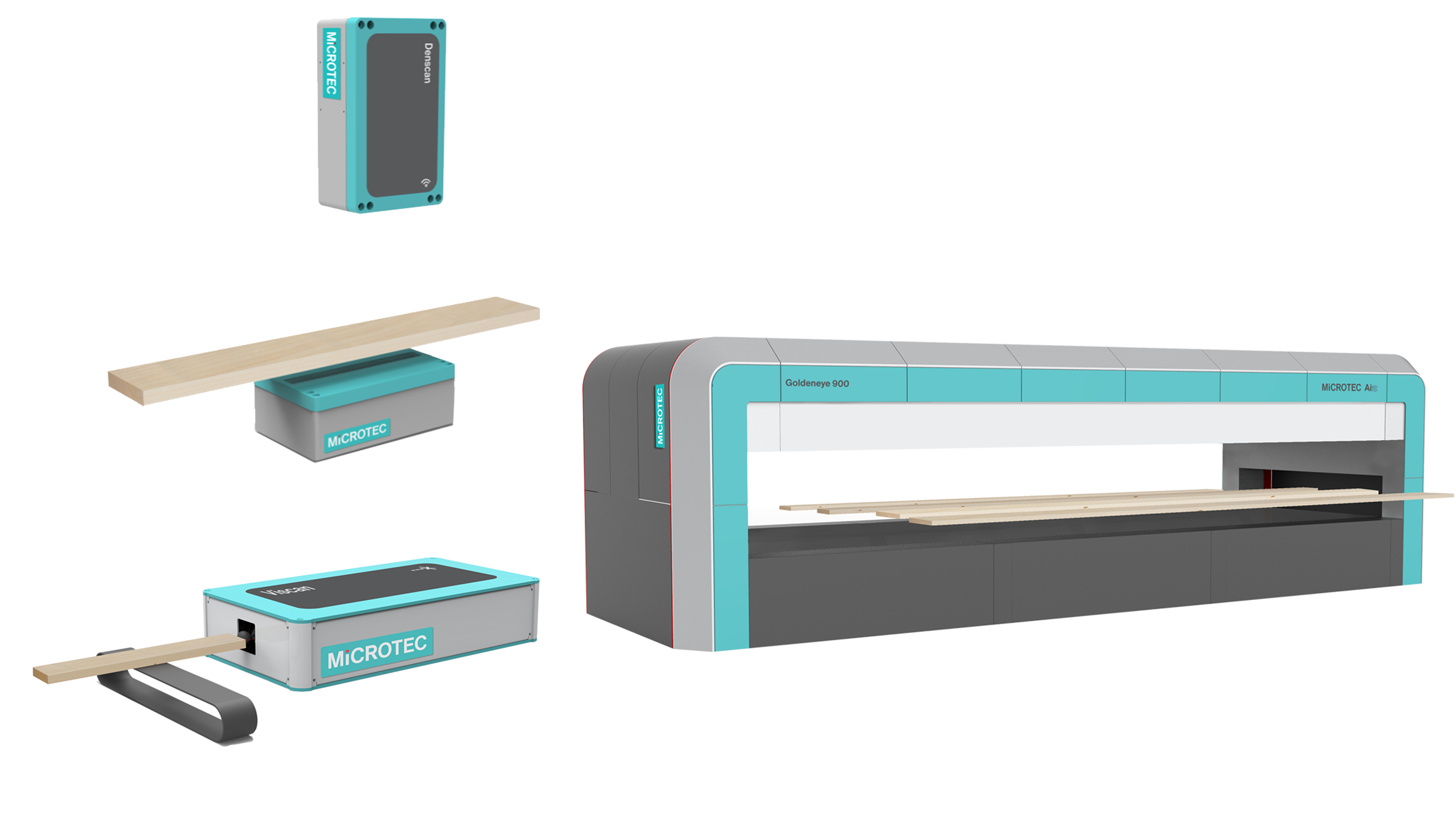

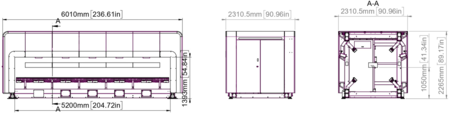

Engineered for effortless integration into your production line, the Goldeneye 900 features a compact and optimized footprint for increased efficiency. The transportation level has been lowered to 1050 mm, creating additional clearance beneath the chains. Additionally, the total height has been reduced by 390 mm and the width by 100 mm, maximizing space utilization while maintaining peak performance.

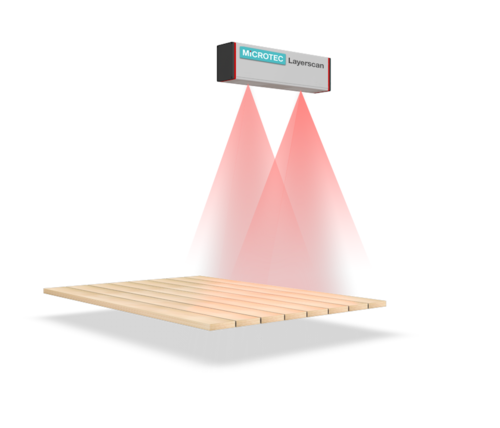

Pure Quality and Precision

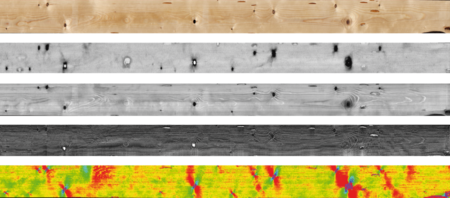

The Goldeneye multi-sensor quality scanner accurately detects wood defects, grades, and classifies lumber using scattering laser, 3D laser, and color imaging. It determines the overall quality of green, dry, and planed lumber on all four sides, providing best-in-class optimization. One optimizer allows you to grade your lumber at all different stages of your production.

Powered by MiCROTEC Ai

Artificial Intelligence (Deep Learning AI) is integrated into all quality scanners from log to finished board. The AI knowledge of all MiCROTEC companies is merged into the MiCROTEC Ai platform, raising the possibilities of Deep Learning AI in the wood industry to a completely new level.

Overview chart

Technology

- 3D Laser

- Scattering Laser

- Color

- MiCROTEC Ai

Technical Data

- Speed up to 240 lugs/min

- Thickness up to 150 mm/6"

- Width up to 610 mm/24"

Applications

- Sorting

- Trimming

- Grading

- Cross-cutting

- Edging & Ripping

Features

- Cut-in-2

- Warp profile

- NGR optimization

- Pith Finder for knot connection

- Slope of grain

- Finger joint optimization (CLT-GLT)

- MiCROTEC Connect

- Growth Ring Map

Certifications

- SE: EN 14081

Options

- Moisture profile

- Pith Position

- Synchronization suite

- Simulation suite

- MOE & MOR

Customer Quote

Goldeneye Models

Contact form