Goldeneye Transverse: Significantly Higher Yield at Binder

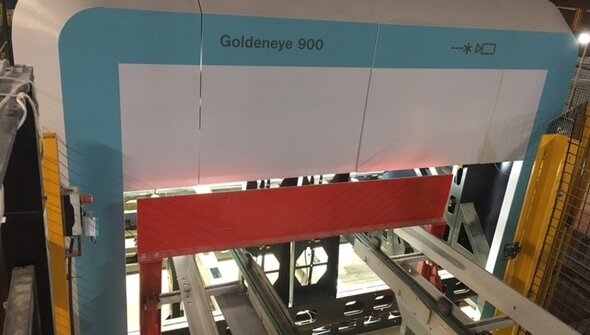

Before the scanners were installed, lumber sorting was done manually. After the decision had been made to invest in South Tyrolean technology, the Goldeneye 900 was installed during the company’s 2022 Christmas shutdown. To make room for the scanner, the grading station had to be shortened.

High Speed

Creuzberger estimates the maximum speed of this scanner at 220 cycles per minute. First, the boards pass through the Goldeneye 900, where they are visually evaluated. “We use an AI-based network to detect the points where the boards rest on the chain. This eliminates any blind spots,” Creuzberger explains.

After visual sorting, each board can be marked for the QC Assist quality control tool using an ID printer. This way, lumber with thicknesses from 17 to 130 mm, widths between 55 and 305 mm, and a maximum length of 5.2 m can be sorted. The boards are then sorted into a twelve-level storage area.

Traceable Board Information

Once they have left the Goldeneye 900, the boards pass through an X-ray scanner where the respective density is determined. For this purpose, MiCROTEC installed a total of four X-ray modules. In the final step, the Viscan, a high-performance laser vibrometer, optionally determines the modulus of elasticity of each lamella based on the resonance frequency. All information, such as wood moisture content, dimensions, strength, and visual evaluation results, can be accessed virtually via the QC Assist software and tracked via a code applied to the board. The scanner software makes it easy to retrieve individual board data and production statistics.

“The Goldeneye 900 in Kösching laid the foundation for further joint scanner projects. At the moment, a total of five Goldeneye 900 scanners are in use at various Binderholz sites,” Creuzberger says and adds: “All the scanners that followed were based on the ‘blueprint’ of the Goldeneye 900 in Kösching in order to strengthen synergies within the Binderholz Group.”

In addition to making work easier for employees, the MiCROTEC scanner guarantees objective lumber evaluation at all times. Furthermore, Binderholz reported a significant increase in yield. Lumber to be exported to the US was previously sorted more conservatively to avoid markdowns. Now, yield has gone up by up to 20%.

The full article from TIMBER-ONLINE can be found here.